In situ crankshaft repair has become the most preferred solution for restoring damaged crankshafts in marine engines, power plants, and heavy industrial equipment. Instead of disassembling and shipping the crankshaft to a workshop, RA Power Solutions executes precision crankshaft grinding and polishing on-site or onboard boats, considerably saving downtime and costs.

With over 45 years of global experience, RA Power Solutions delivers reliable and proven in situ crankshaft repair services across more than 100 countries, including emergency repairs during port stays or voyage schedules.

What Is In Situ Crankshaft Repair?

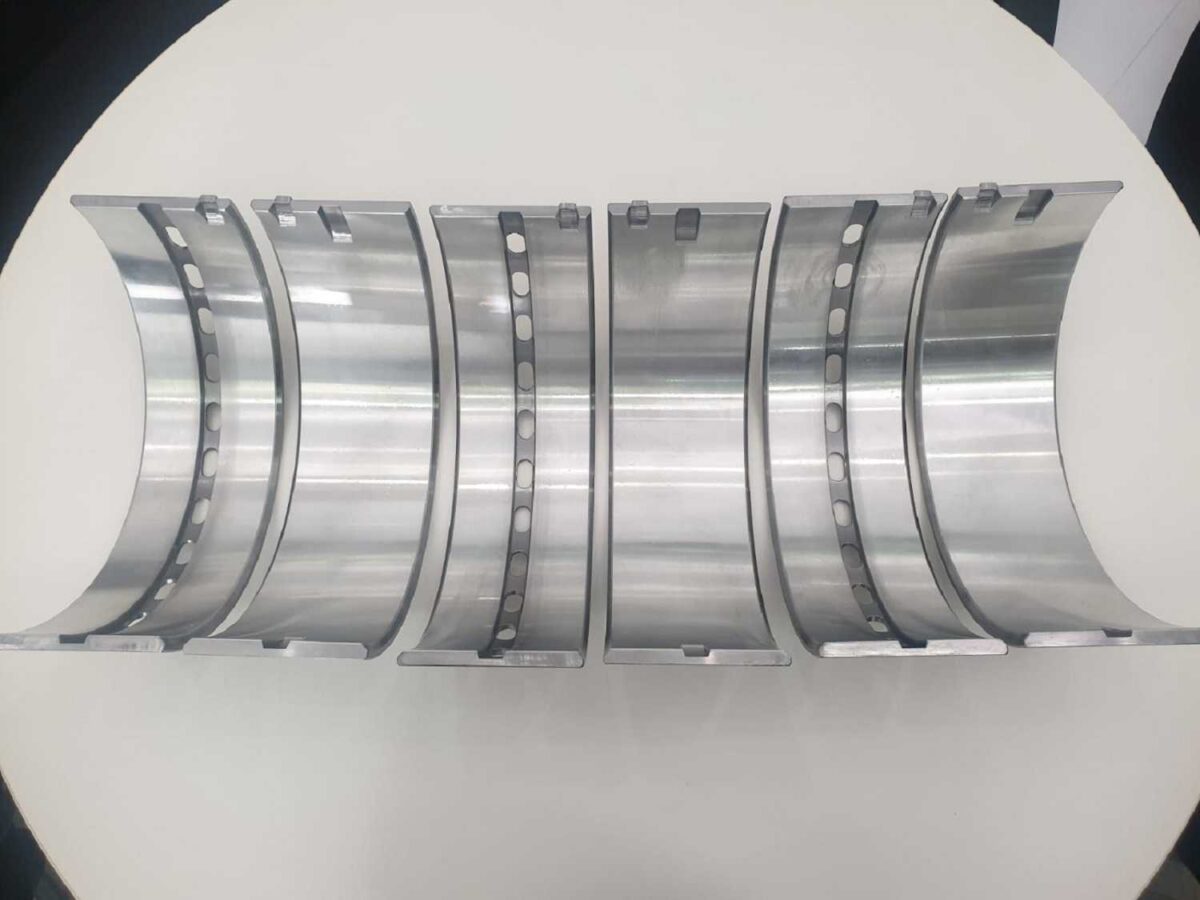

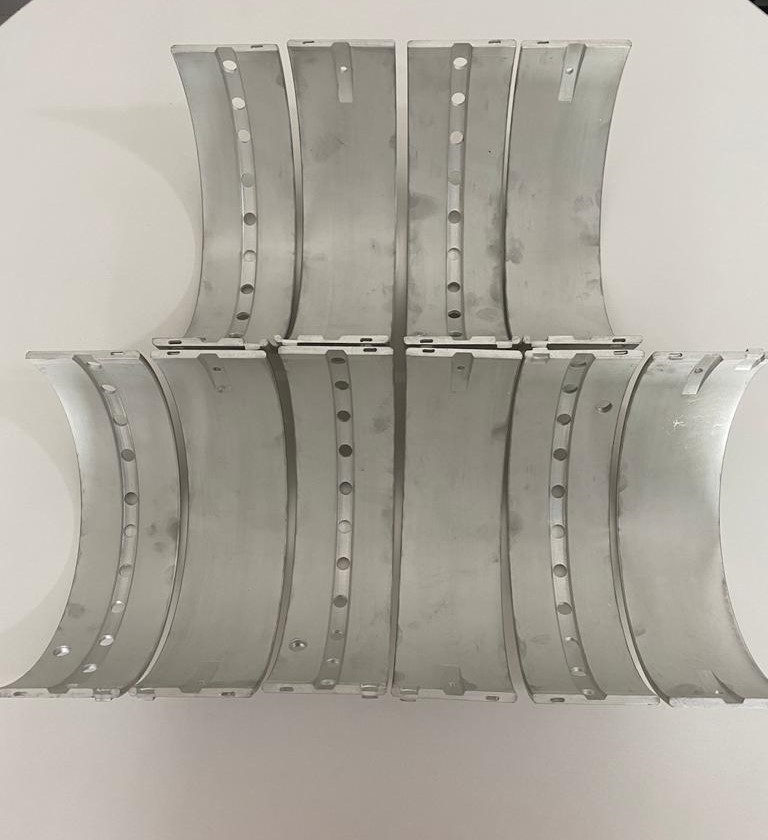

In situ crankshaft repair is a specialised machining procedure that grinds and polishes damaged crankpins or main journals without removing the crankshaft from the engine block. Repairs are performed with micron-level accuracy while keeping OEM tolerances.

This method is ideal for:

- Marine diesel engines

- MAN B&W, Wartsila, Sulzer, Caterpillar engines

- Power plant engines

- Offshore and industrial engines

Why Choose In Situ Crankshaft Repair?

Choosing in situ crankshaft repair offers multiple advantages:

- Eliminates crankshaft removal and reinstallation.

- Reduces engine downtime drastically.

- Avoids transportation and workshop costs.

- Enables emergency repairs during voyages or port calls.

- Restores crankshaft geometry and surface finish accurately.

RA Power Solutions provides exact alignment, correct fillet radii, and surface roughness in accordance with manufacturer standards.

In Situ Crankshaft Repair by RA Power Solutions

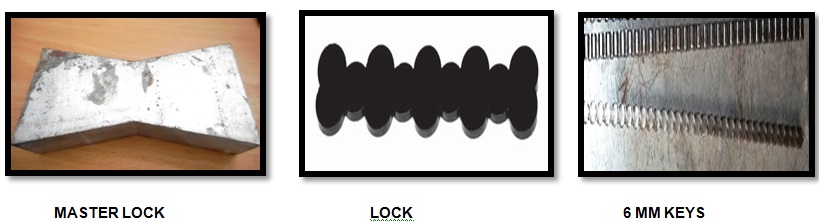

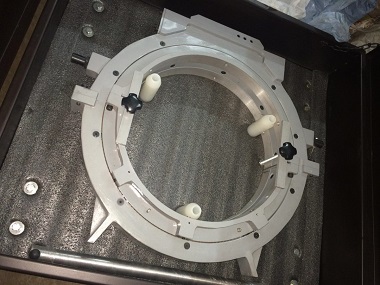

RA Power Solutions deploys highly trained technicians equipped with portable, in situ crankshaft grinding and polishing machines worldwide. Our services include:

- Crankpin grinding and polishing

- Main journal grinding

- Ovality and taper correction

- Crankshaft inspection and calibration

- Bearing inspection and replacement support

We regularly execute In Situ Crankshaft Grinding Repair onboard vessels and at sites in Bahrain, Bangladesh, India, Japan, Kuwait, Qatar, Oman, the Philippines, Indonesia, Iran, Iraq, Dubai, Singapore, Madagascar, Abu Dhabi, Azerbaijan, the UAE, and many more.

Industries We Serve:

- Marine & Shipping

- Power Generation

- Offshore Oil & Gas

- Heavy Engineering

- Mining & Industrial Plants

Our proven track record makes us a trusted partner for ship owners and power plant operators worldwide.

For expert assistance on portable crankshaft grinding machines, In Situ Crankshaft Grinding Repair, onsite grinding of crankshafts, and main journal grinding equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

It is a repair method where crankshaft grinding and polishing are performed onsite without removing the crankshaft from the engine.

Marine, power plant, and industrial engines, including MAN B&W, Wartsila, Sulzer, and Caterpillar engines.

Repairs are carried out with micron-level accuracy, maintaining OEM specifications for alignment and surface finish.

It saves time, reduces cost, avoids dismantling, and minimises operational downtime.

Yes, RA Power Solutions offers 24/7 global onsite crankshaft repair services across ports, power plants, and industrial sites.

In situ crankshaft repair has become the most preferred solution for restoring damaged crankshafts in marine engines, power plants, and heavy industrial equipment. Instead of disassembling and shipping the crankshaft to a workshop, RA Power Solutions executes precision crankshaft grinding and polishing on-site or onboard boats, considerably saving downtime and costs. With over 45 years … Continue reading “In Situ Crankshaft Repair – Advanced Onsite Engine Restoration | Iraq”