RA Power Solutions successfully repaired the Crankshaft of Himsen Hyundai 6H17/28 engine at MIP Mersin, Turkey. The engine, owned by an Italian company, experienced a major breakdown due to a failure in one of its auxiliary engines.

RA Power Solutions promptly deployed two skilled technicians equipped with onsite crankshaft grinding tools. The repair was efficiently conducted while the vessel remained anchored at MIP Mersin, ensuring minimal downtime and reliable restoration of the engine.

Following are the major Engine and Crankpin details:

| S. No. | Engine and Crankpin Details | |

| 1. | Engine Make | HIMSEN HYUNDAI |

| 2. | Engine Model | 6H 17/28 |

| 3. | Crankpin Diameter Standard | 175.00MM |

| 4. | Crankpin Bearing Width | 60.00 MM |

| 5. | Place of Execution of Grinding of Crankpin | MIP Mersin, Turkey |

| 6. | Name of Shipping Company | Reputed Company from Italy |

Key Observations of the Crankshaft:

Visual Inspection Findings:

(i) The breakdown was caused by the failure of the lubricating oil pump, resulting in damage to all connecting rod bearings.

(ii) Bearing material was embedded on all six crankpins and was meticulously removed.

(iii) Dimensional inspection conducted after polishing revealed taper and ovality measurements ranging from 0.22 mm to 0.86 mm.

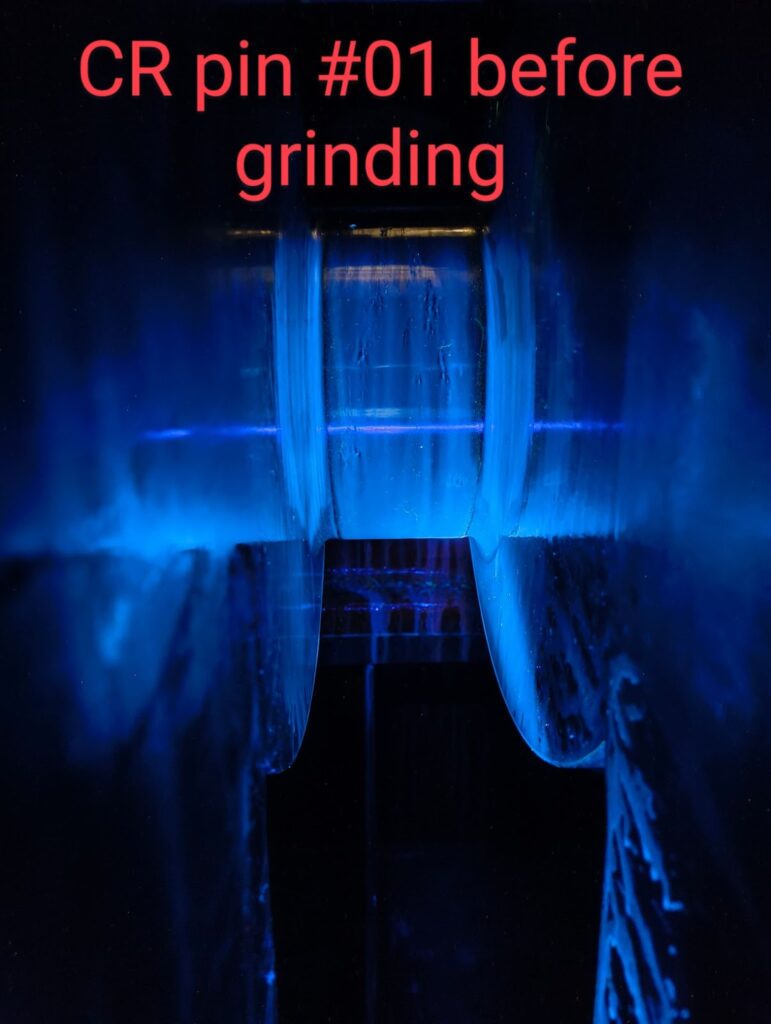

MPI Test Before Crankshaft Grinidng and Repair

Image Showing Before Grinding and Polishing

The Dimensional Inspection Report of Six (6) Number Crankpins of HIMSEN HYUNDAI 6H 17/28:

| SIZE OF CR PINS BEFORE REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | STD | Ovality | |

| CR-1 | 174.74 | 174.85 | 174.62 | 174.73 | 174.66 | 174.88 | 174.62 | 175.00 | 0.38MM |

| CR-2 | 174.83 | 174.92 | 174.80 | 174.78 | 174.83 | 174.93 | 174.78 | 175.00 | 0.22MM |

| CR-3 | 174.70 | 174.90 | 174.55 | 174.69 | 174.48 | 174.54 | 174.48 | 175.00 | 0.52MM |

| CR-4 | 174.78 | 174.88 | 174.79 | 174.72 | 174.79 | 174.92 | 174.72 | 175.00 | 0.28MM |

| CR-5 | 174.78 | 174.88 | 174.76 | 174.92 | 174.72 | 174.78 | 174.72 | 175.00 | 0.28MM |

| CR-6 | 174.22 | 174.80 | 174.14 | 174.78 | 174.37 | 174.85 | 174.14 | 175.00 | 0.86MM |

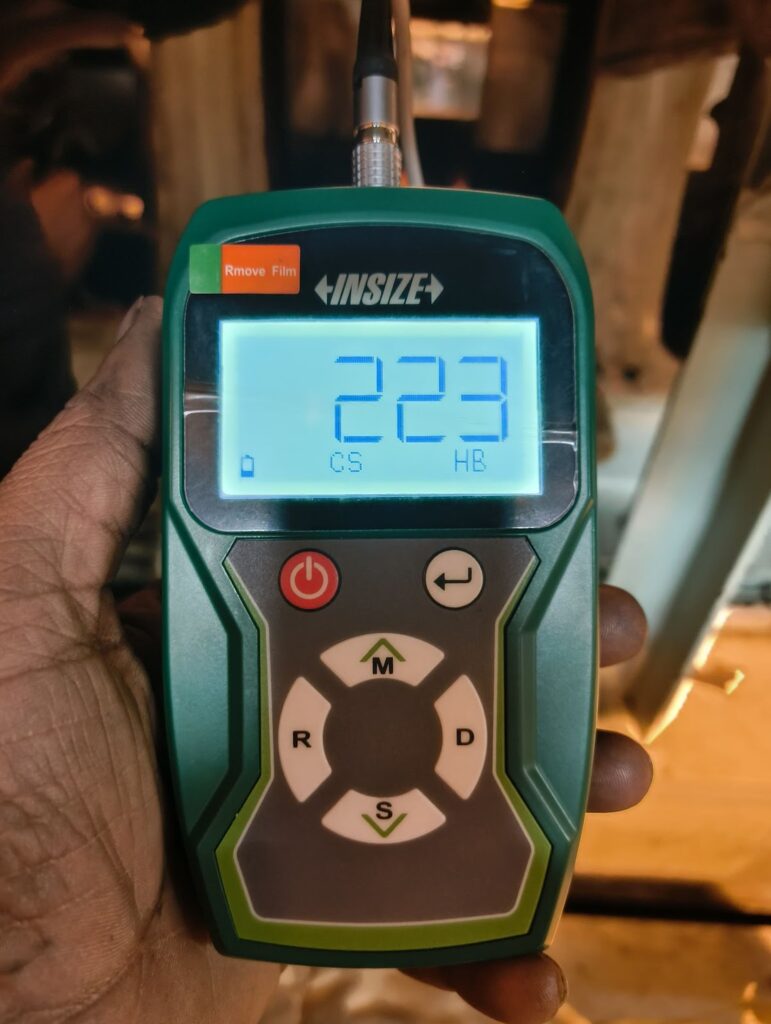

(iv) Hardness testing indicated acceptable levels overall, with minor exceptions in a few areas, which were assessed as non-critical.

(vi) Magnetic Particle Inspection (MPI) revealed minor hairline cracks, while all other parameters remained within acceptable limits.

CR Pin Before Grinding of HIMSEN HYUNDAI 6H 17/28

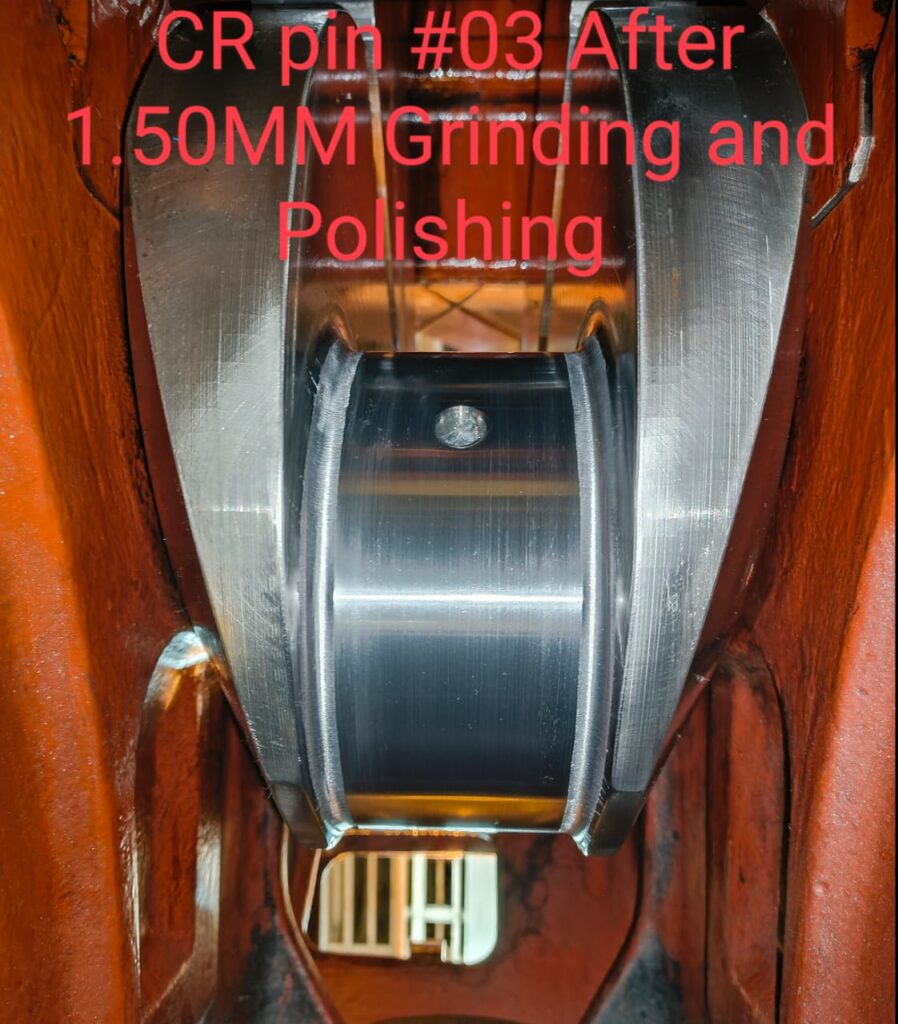

Actions Taken by RA Power Solutions Technicians:

1. The grinding of all six (6) crankpins was undertaken by our insitu crankshaft grinding machine.

2. Three (3) number of crankpins diameter was reduced by 1.00 MM and the final size was maintained as 174.00 MM.

3. Three (3) number of crankpins diameter was reduced by 1.50 MM and the final size was maintained at 173.50 MM.

Final Report After Grinding is Pasted Below:

| SIZE OF CR PINS AFTER REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | U/S | Ovality | |

| CR-1 | 173.48 | 173.49 | 173.49 | 173.48 | 173.50 | 173.50 | 173.48 | 173.50 | 0.02MM |

| CR-2 | 173.98 | 173.99 | 174.00 | 173.99 | 173.98 | 173.99 | 173.98 | 174.00 | 0.02MM |

| CR-3 | 173.49 | 173.50 | 173.50 | 173.48 | 173.49 | 173.50 | 173.48 | 173.50 | 0.02MM |

| CR-4 | 173.98 | 173.99 | 173.98 | 174.00 | 173.98 | 174.00 | 173.98 | 174.00 | 0.02MM |

| CR-5 | 173.99 | 173.99 | 173.98 | 174.00 | 173.98 | 173.99 | 173.98 | 174.00 | 0.02MM |

| CR-6 | 173.48 | 173.49 | 173.49 | 173.50 | 173.50 | 173.48 | 173.48 | 173.50 | 0.02MM |

We ensure all six crankpins are maintained with a stringent tolerance of 0.02 mm, delivering exceptional accuracy and optimal performance in every project.

Global Expertise in Crankshaft Repair

RA Power Solutions is a global leader in onsite crankshaft repair and grinding services. With extensive experience, we have successfully completed projects across the globe, including Dubai, Fujairah, Qatar, Saudi Arabia, Oman, Iraq, Togo, Malta, Freetown, Egypt, Malaysia, Iran, Indonesia, Vietnam, Jordan, and many other locations.

Our highly skilled technicians are available 24/7 and can be deployed at short notice. Many of our team members hold valid US visas, allowing us to serve clients in South America, the Caribbean, and other regions efficiently.

Get in Touch for Professional Crankshaft Services:

Email: rajshahani@rapowersolutions.com | info@rapowersolutions.com

Phone: +91 9582647131 | +91 9810012383.

RA Power Solutions successfully repaired the Crankshaft of Himsen Hyundai 6H17/28 engine at MIP Mersin, Turkey. The engine, owned by an Italian company, experienced a major breakdown due to a failure in one of its auxiliary engines. RA Power Solutions promptly deployed two skilled technicians equipped with onsite crankshaft grinding tools. The repair was efficiently … Continue reading “On Site Crankshaft Repair of HIMSEN HYUNDAI 6H 17/28 | Turkey”