The main engine and auxiliary engine maintenance, overhauling, and repair is undertaken by RA Power Solutions for the last forty years for the engine installed on vessels, diesel engine driven power plants, and heavy industries.

It is important that periodic maintenance and overhaul schedule of the diesel engine is followed in order to avoid any major breakdown. RA Power Solutions has a team of experienced engineers who can be deputed to any site of powerplant or the vessel on short notice to undertake the overhauling and repair of engine.

We undertake the following jobs:

- Periodic maintenance and overhauling of engines, including alternator and electric panels.

- Shifting of diesel generating set from one site to another site is done on a turnkey basis.

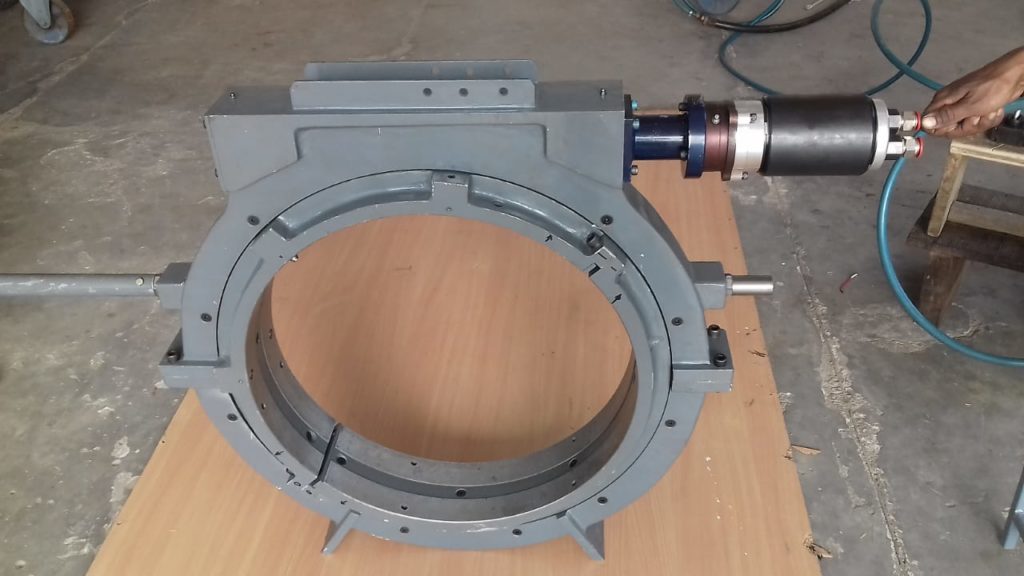

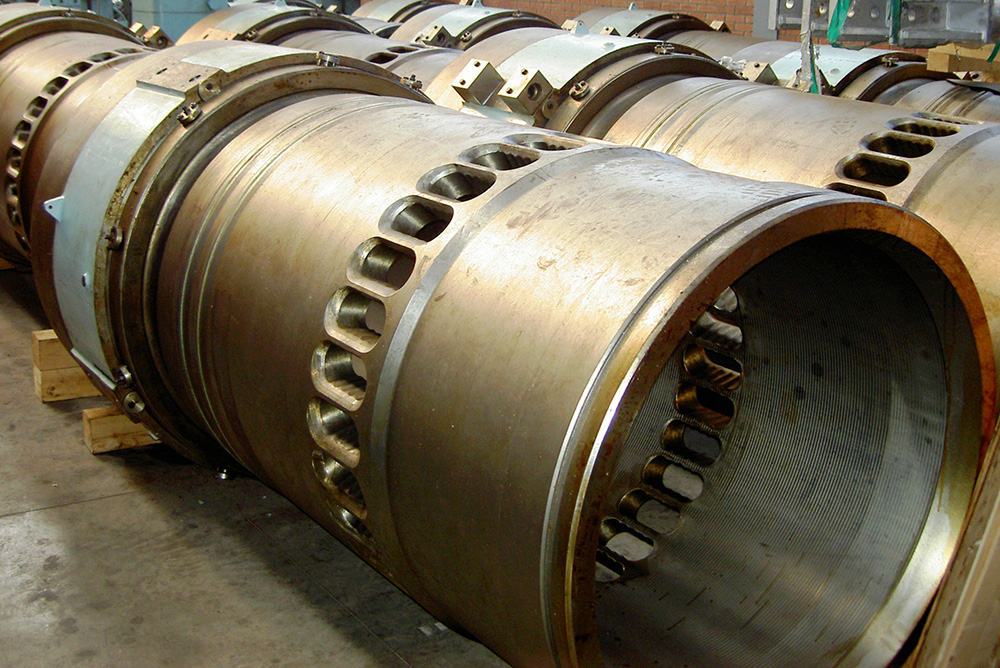

- Inspection of engine block, crankshaft, cylinder liners, pistons, connecting rod, and cylinder head wherever required.

- We also undertake onsite repair of major components, which is of great advantage to our clients.

- Replacement of crankshaft requires special skills, calibration, and following of instructions specified by the engine manufacturer.

- We specialize in the replacement of crankshaft due to accident or wear and tear.

We are trusted by the shipping companies and the industry based all over the world and have been regularly serving our clients based in Nigeria, Qatar Dubai, Singapore South America, and many other countries.

Marine Engine Spares

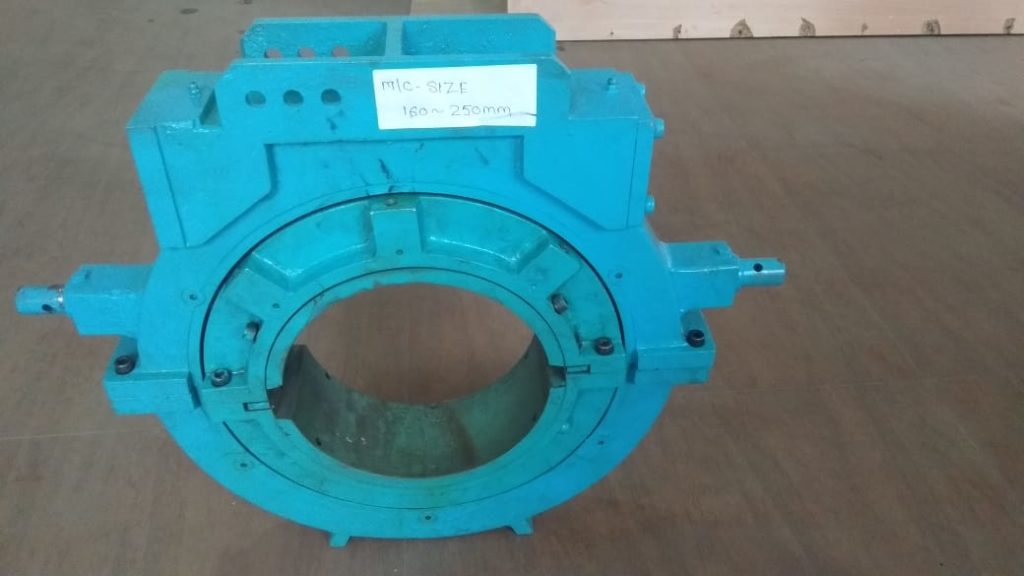

While undertaking the engine maintenance and overhauling, we have observed that in some cases the engine spare parts are not available. This is most common for the engines which have been discontinued by the manufacturer or the manufacturers have stopped manufacturing of diesel engines in totality.

RA Power Solutions Pvt. Ltd. plays a very important role in this area as parts for popular makes of diesel engine and models are available in stock. We have developed various spares like cylinder liners, bearings, etc which are regularly exported all over the world. The marine engine spares are also sourced by RA Power Solutions from the world’s largest ship breaking yard based in western India. Ours is the only company that has in-house facilities for undertaking reconditioning of old marine engine parts supported with experienced technicians.

In general, the cost of marine engine spare parts offered by us are priced substantially lower than the prices offered by the engine manufacturer. All the spares supplied are supported with a performance guarantee and with the calibration reports in detail.

The author is Mr. Raj Shahani, Managing Director of the company. He is having forty years of experience in providing services like onsite diesel engine repair, marine diesel engine maintenance, main engine maintenance, overhauling of marine engine, and repair of marine engine, overhauling and repair of diesel engine, and many other services related to high-capacity engine.

We provide top overhauling of diesel engine, marine engine cylinder liners, engine overhauling, maintenance and repair services, overhauling of diesel engine, engine overhaul services and crankshaft repair services. For any information on our services, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

The main engine and auxiliary engine maintenance, overhauling, and repair is undertaken by RA Power Solutions for the last forty years for the engine installed on vessels, diesel engine driven power plants, and heavy industries. It is important that periodic maintenance and overhaul schedule of the diesel engine is followed in order to avoid any … Continue reading “Main Engine Maintenance | Overhauling of Marine Engine and Diesel Engine”