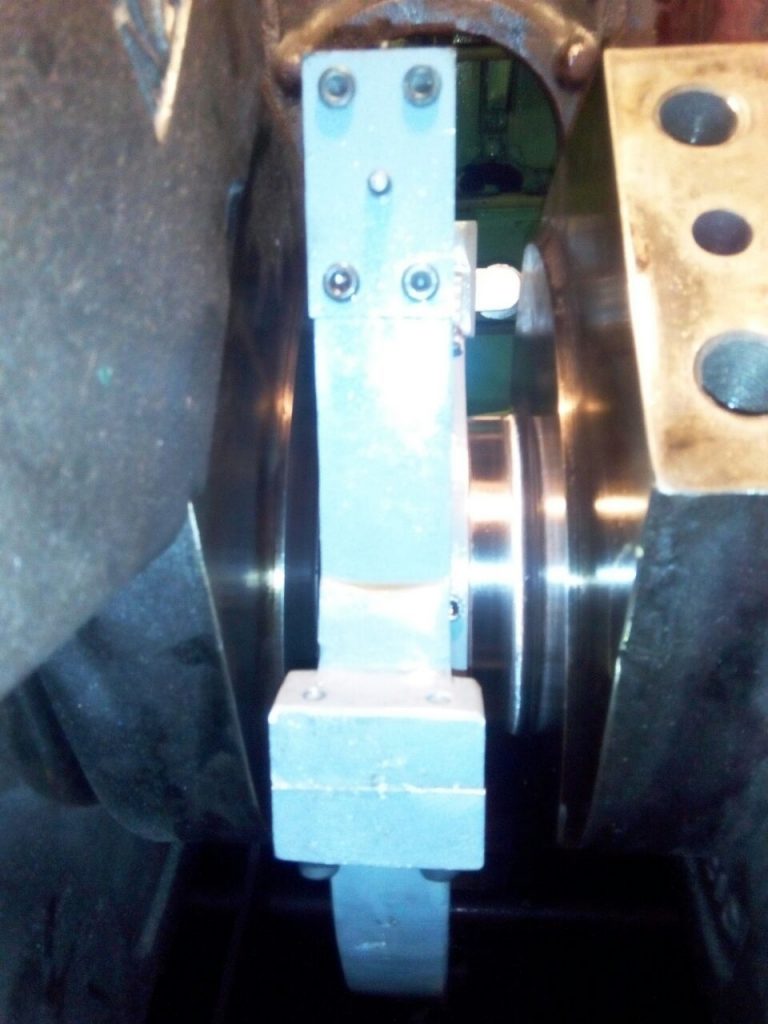

Cylinder liners up to the length of 1500 mm are manufactured by us. We strictly follow the centrifugal process for casting of cylinder liners. The material composition of cylinder liners is maintained strictly as per the manufacturer’s specifications.

We develop and manufacture cylinder liners either as per the drawing or as per the sample. The casting of cylinder liners after the centrifugal process is checked thoroughly by our technicians for blow holes, porosity, and any casting flaw.

The cylinder liner is machined on the latest breed of CNC equipment, which helps us to maintain close tolerances. The honing operation of cylinder liners is done in-house, maintaining the surface finish angle and profile as per the requirement. We regularly export large quantity of engine cylinder liners. We are considered to be quality-conscious and are a competitively priced cylinder liners exporter.

We have cylinder liners of the following makes in stock:

ABB, ABC, Anglo Belgian Corporation, Akasaka, Alco Diesel Engines, Alfa Laval, Allen, Alpha Diesel, Alstom, B & W, Bergen Diesel Engines, Blackstone, Bosch, Caterpillar, Cegielski, Consilium, Crepelle, Cummins, Daihatsu, Detroit Diesel, Deutz, DeutzMarine Engine, EMD, Fiat, FUJI, Fuji Diesel, Furuno, Hanshin, Headway, HIMSEN, Holset, Hyundai, JRC, Kawasaki, Kelvin Hughes, Kongsberg Maritime, L’OrangeMaschinenfabrik, MaK, MAN, MAN B&W, Martek Marine, Mirrlees Blackstone, Mitsubishi, Mitsubishi UE/UEC, MTU, MWM, Napier, NAVTEX, Nigata, Nohab Diesel, Paxman, Pielstick, Ruston & Hornsby, Samsung, Simrad, SKL, Sperry, Stork SW Diesel, Stork Werkspoor, STORK-WARTSILA DIESEL, Sulzer, Volvo Penta, Wartsila, Wartsila Diesel, Westfalia, Wichmann, Woodward, Yanmar, etc.

For more information regarding cylinder liner repair, email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Cylinder liners up to the length of 1500 mm are manufactured by us. We strictly follow the centrifugal process for casting of cylinder liners. The material composition of cylinder liners is maintained strictly as per the manufacturer’s specifications. We develop and manufacture cylinder liners either as per the drawing or as per the sample. The … Continue reading “Cylinder Liners – RA Power Solutions”