It is generally observed that whenever there is a failure of bearing, it causes serious damage to the crankshaft. The crankpin and main journal develop excessive ovality, deep bearing line marks are observed and in some cases, the impact of failure is so high that it leads to depression/cuts on the crankpin. In this situation, crankshaft needs grinding and polishing.

In Situ Crankpin Machining | Onsite Crankshaft Grinding & Polishing Offered by RA Power Solutions:

In case of failure of the crankshaft, RA Power Solutions undertakes in situ crankshaft grinding and polishing. We have a team of experienced technicians and our response time to an emergency breakdown situation is minimum. All our technicians hold valid Indian CDC and can fly to any destination worldwide in the minimum possible time. Technicians can also sail on the vessel and can undertake the repairs.

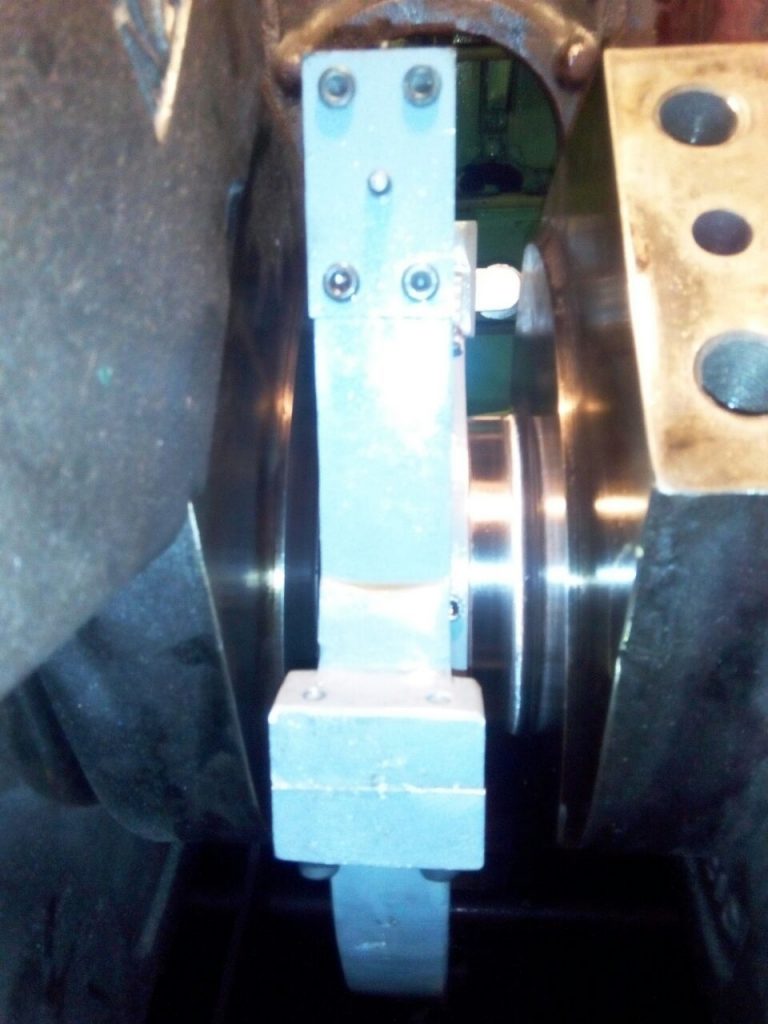

The crankshaft is repaired with minimum downtime, as there is no requirement of removal of crankshaft from the engine block. We have in situ crankshaft grinding machine available in the range of 35 mm to 700 mm to cater to the emergency breakdown.

In Situ Crankshaft Grinding & Polishing | Four-Decade of Experience

It is important that after damage and failure of crankshaft, it is thoroughly inspected by an experienced technician, and all the major parameters are recorded. The planning for the repair is done, and the crankshaft is repaired successfully. We possess the latest and calibrated instrumentation to conduct the pre and final inspection of the crankshaft. The crankshaft grinding equipment used for in situ grinding and polishing is of the latest design with minimum vibration. This facilitates us to maintain generally the tolerance after grinding within 10 to 20 microns and a surface finish of less than 0.2 micrometers in terms of RA value. These tolerances are far better than the tolerances specified by the manufacturer.

In Situ Repair of Crankshaft | Reduce Maintenance Cost

The industries and the shipping companies are well aware of exorbitant rates charged by the few selected companies based in Europe for in situ repair of crankshaft. RA Power Solutions have changed this trend worldwide. Our charges are the most reasonable and lowest in the world with international standards. Our in situ crankshaft repair is cost-effective with minimum downtime and avoids costly replacement.

Benefits of In Situ Crankshaft Repair by RA Power Solutions

- We have in house team of trained and experienced technicians who can be deputed at your site with in situ crankshaft grinding and polishing machine in minimum time.

- We extend 24*7 services worldwide with a guarantee.

- More than forty years of experience in crankshaft repair has proven us to be leaders in this field.

- Excellent analytical ability because of experience and the use of modern instruments can save your crankshaft from rejection.

We recommend inspection by our technician prior to planning any repair procedure. Most reliable company working for leading industries and shipping companies. References can be provided on request.

For any information on onsite machining, insitu crankpin grinding, on site machining services and onsite machining of crankshaft please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

It is generally observed that whenever there is a failure of bearing, it causes serious damage to the crankshaft. The crankpin and main journal develop excessive ovality, deep bearing line marks are observed and in some cases, the impact of failure is so high that it leads to depression/cuts on the crankpin. In this situation, … Continue reading “In Situ Crankshaft Machining | Insitu Crankpin Grinding | Onsite Machining of Crankshaft”