We are the leaders and specialists in the repair and rebabbitting of white metal bearing. We understand the importance of white metal Babbitt bearings as we have been working in the field of repair, maintenance, and operation of high-capacity diesel engines, turbines installed in power plants, and the heavy engineering industry.

Understanding the importance of repair of white metal Babbitt bearings, we have designed a procedure for rebabbitting of old white metal babbitt bearings which not only delivers satisfactory performance but also ensures the long life of bearings after the Rebabbitting process is undertaken by us.

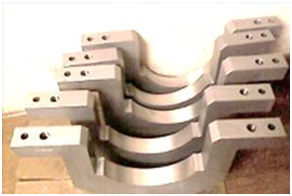

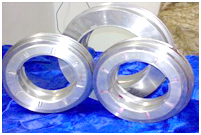

Repair of old white metal bearing

We at RA Power Solutions believe that rebabbitting of old damaged bearings is more complexed than the manufacturing of new white metal bearings . For the repair of Babbitt bearings, various quality control checks are necessary prior to the undertaking of Rebabbitting of white metal. Our experienced technicians follow strictly the procedure laid down in the manual before white metal Rebabbitting and even after the Rebabbitting of bearing and final machining is undertaken.

The correct selection of Babbitt white metal is again of great importance. In most of the cases since the bearings are old, the users are not aware about the grade of white metal which is used at the time of manufacturing of bearing. The old Babbitt metal after removal is subject to metallurgical composition check in order to know the grade and composition of white metal.

Our endeavor is always to use the babbitt white metal of higher grade than the existing one which is really appreciated by our clients as they not only get the satisfactory performance of Babbitt white metal bearings but also long life of the bearings which are rebabbitted by us.

Advantage of getting rebabbitting and repair of old white metal bearings from RA Power Solutions.

We have observed that in most of the cases end-user replaces the bearings without inspection of bearing sitting area of the shaft. Due to the wear and tear, failure of bearing, bearing line marks, pitting, and various other flaws are observed on the bearing sitting area of the shaft and they need to be removed prior to the assembly of the rebabbitt bearing.

RA Power Solutions have onsite crankshaft grinding and polishing equipments upto 700 mm diameter. These equipments can be send to any site all over the world to undertake polishing of the bearing sitting area of the shaft. Our portable, lightweight onsite shaft polishing machines can undertake the polishing and improve the surface finish without removal of the shaft from the main equipment. The polishing of shaft and enhancement of surface finish results to the long life of not only the repaired white metal Babbitt bearing but also of the shaft.

The types of bearing we manufacture and undertake rebabbitting are not limited to the following categories:

- Diesel engines

- Pumps

- Generators

- Compressors

- Gear boxes

- Propeller shaft bearings

- Turbines, alternator, and for all applications

For more information on babbitt metal, Rebabbitting of white metal bearing and bearing remetallic, tri-metal bearing, engine bearing, and white metal bearing repair contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

We are the leaders and specialists in the repair and rebabbitting of white metal bearing. We understand the importance of white metal Babbitt bearings as we have been working in the field of repair, maintenance, and operation of high-capacity diesel engines, turbines installed in power plants, and the heavy engineering industry. Understanding the importance of … Continue reading “Repair and Rebabbitting of White Metal Bearing”