Cracks in cast iron and other metal components can lead to significant operational challenges in the power generation, marine, manufacturing, and heavy engineering industries. Traditional repair methods, like welding, often introduce thermal stress, weakening the material over time. With over 44 years of experience, RA Power Solutions specializes in metal stitching and metal locking, two highly effective cold repair techniques that restore the integrity of cracked components without causing additional damage.

What is Metal Stitching?

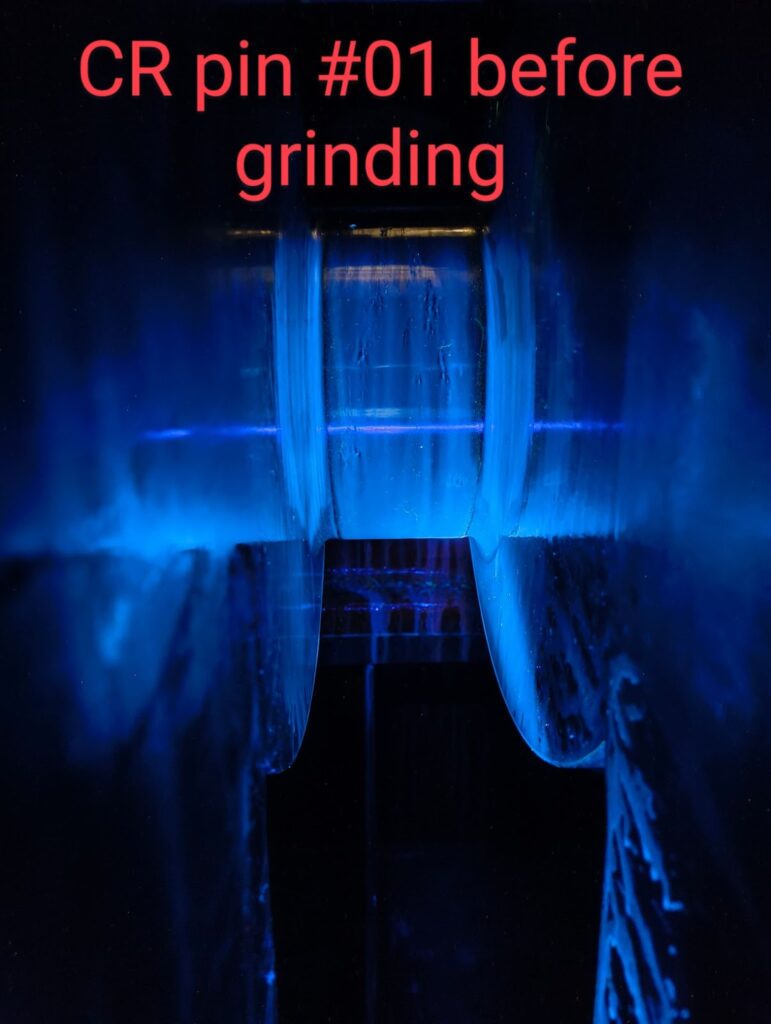

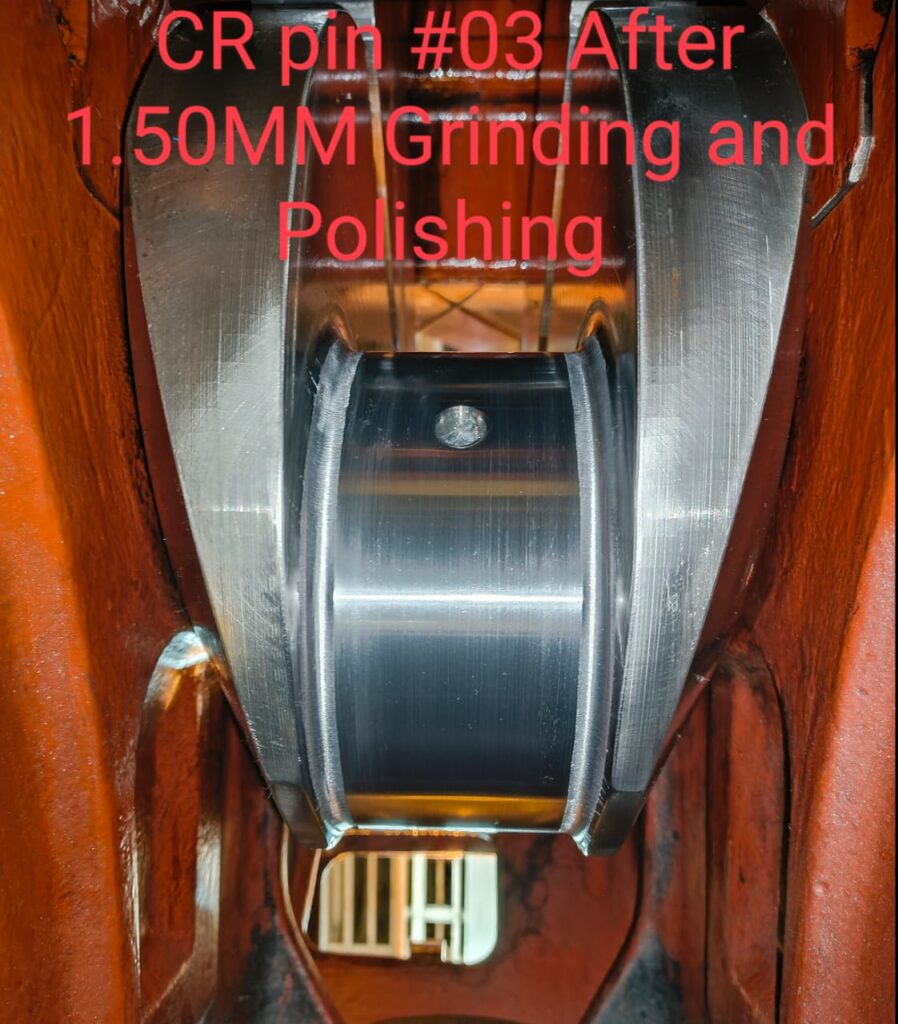

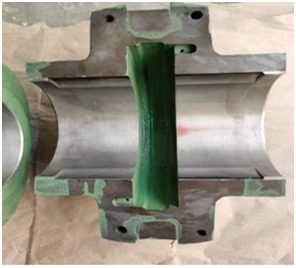

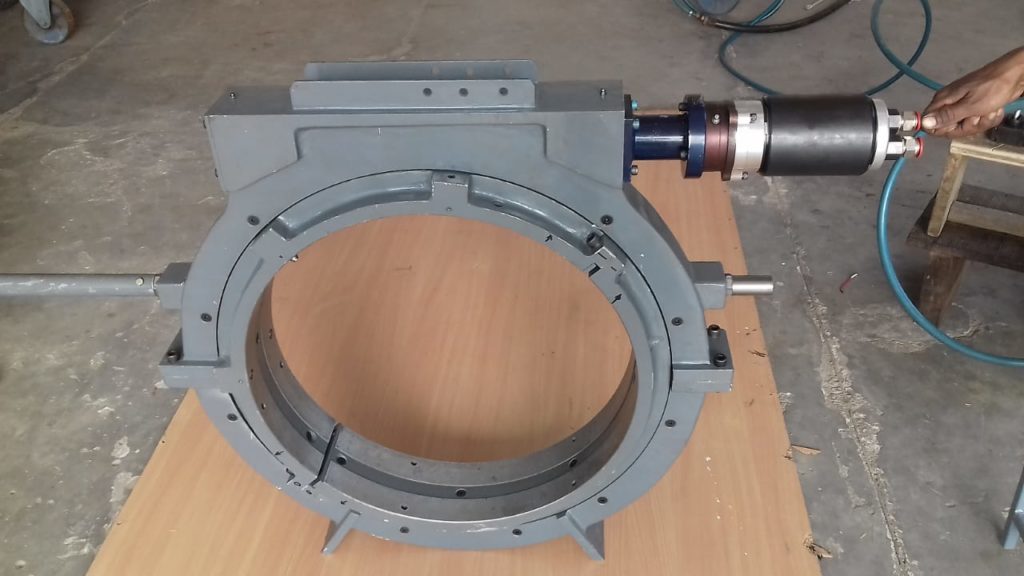

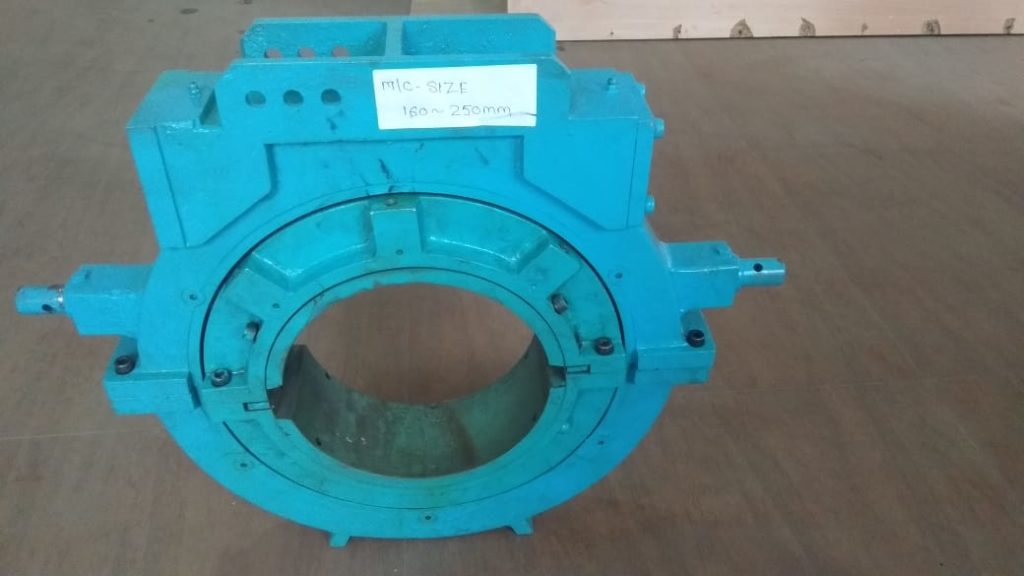

Metal stitching is a cold repair method for mending cracks in cast iron, aluminum, and other metals without welding. It involves drilling precise holes along the crack, inserting metal stitching pins, and locking the pieces together to restore the component’s original strength. This technique is ideal for engine blocks, turbine casings, compressors, and other high-stress industrial machinery parts.

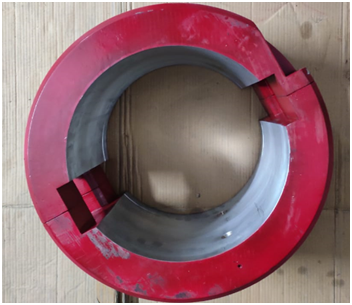

What is Metal Locking?

Metal locking is a reinforcement method used alongside metal stitching. Custom-designed locks are inserted into the stitched area to provide additional support, preventing further crack progression and ensuring a long-lasting repair. This method enhances the durability of the repaired component, making it as strong as or even stronger than the original structure.

Why Choose Metal Stitching and Metal Locking?

Compared to traditional welding, metal stitching and locking offer several advantages:

- Cold Repair Process: No heat is applied, preventing material distortion, stress buildup, and further cracking.

- Onsite Repairs: No need to transport heavy machinery; repairs can be performed at the client’s location, reducing downtime.

- Retains Original Strength: Unlike welding, which can weaken cast iron, metal stitching and metal locking maintain or even improve the structural integrity.

- Cost-Effective: Eliminates the need for expensive replacements and reduces overall maintenance costs.

Benefits of Metal Stitching and Metal Locking

RA Power Solutions has successfully performed repairs for various industries, including:

- Marine Industry: Repairs on ship engine blocks and connecting rods to avoid costly replacements.

- Power Plants: Restoration of turbine casings, generators, and compressors to maintain efficiency.

- Manufacturing Plants: Fixing cracks in heavy-duty machines and industrial equipment.

RA Power Solutions provides metal stitching and metal locking services in countries across Asia, the Middle East, Europe, Africa, and the Americas, including India, UAE, USA, UK, Saudi Arabia, Germany, Singapore, and Australia. With a strong global presence, the company offers onsite repair solutions for industries like marine, power plants, and heavy engineering, helping clients avoid costly replacements and downtime. Their expertise extends to Malaysia, Indonesia, Qatar, Oman, Kuwait, Bangladesh, Sri Lanka, the Philippines, Vietnam, Nigeria, Brazil, Germany, Singapore, Malaysia, Indonesia, and South Africa, ensuring reliable crack repair services worldwide.

For more information regarding repair cast iron, repair crack cast iron, or cast iron repair, crack repair by metal stitching and metal locking, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Cracks in cast iron and other metal components can lead to significant operational challenges in the power generation, marine, manufacturing, and heavy engineering industries. Traditional repair methods, like welding, often introduce thermal stress, weakening the material over time. With over 44 years of experience, RA Power Solutions specializes in metal stitching and metal locking, two … Continue reading “Crack Repair Using Metal Stitching and Metal Locking | RA Power Solutions”